Redefining Replenishment Agility

Understanding demand through sell-through patterns for a product under multiple identifiers ahead of time, and being able to quickly simulate business-specific scenarios, means planners can continually address changes in a much more agile way or even leverage other business functions.

Interconnecting Diwo’s Decision Flows across both Merchandising and Marketing can realign promotions, sync supply with true demand, optimize channel strategy, or even create on-demand audiences at the store/sku or week level.

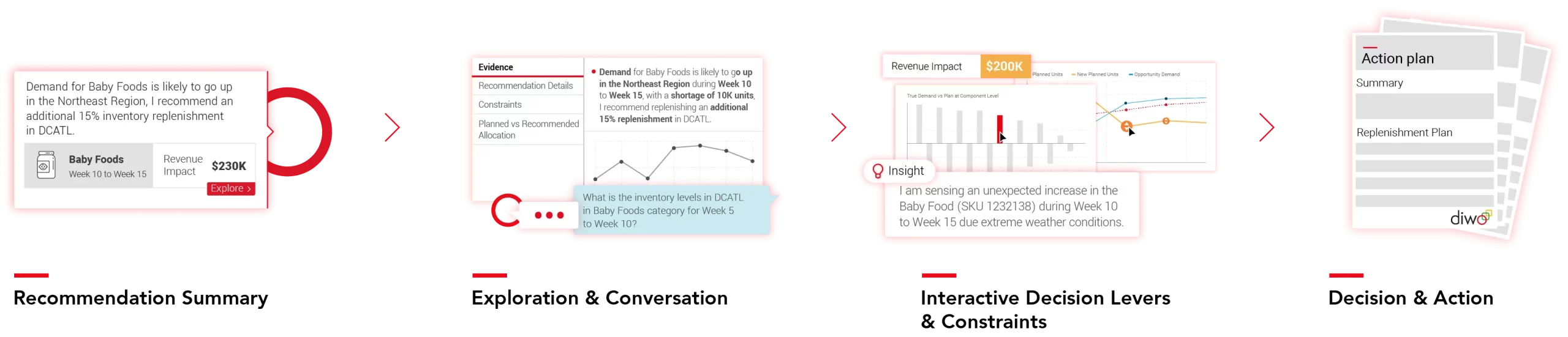

Unlike other Enterprise AI platforms, Diwo’s patented approach to DI focuses on optimizing high-value business decisions, which means time to value is realized much faster and continues to scale across other use cases. Let’s talk about how you can close the gap between insight and action for quicker responses to your Supply Chain scenarios.

Frequently Asked Questions

Replenishment planning is the process of restocking inventory to meet customer demand. Replenishment agility refers to a company's ability to quickly respond to changes in demand and adapt their replenishment strategy. The process involves analyzing sales patterns and forecasting future demand to maintain the right balance of inventory while minimizing costs.